Contact Us

Contacts:Mr.Hu

Whatsapp:+86-13318342201

Tel:+86-18042849825

Contacts:Miss Mai

Fax:+86-0757-28872082

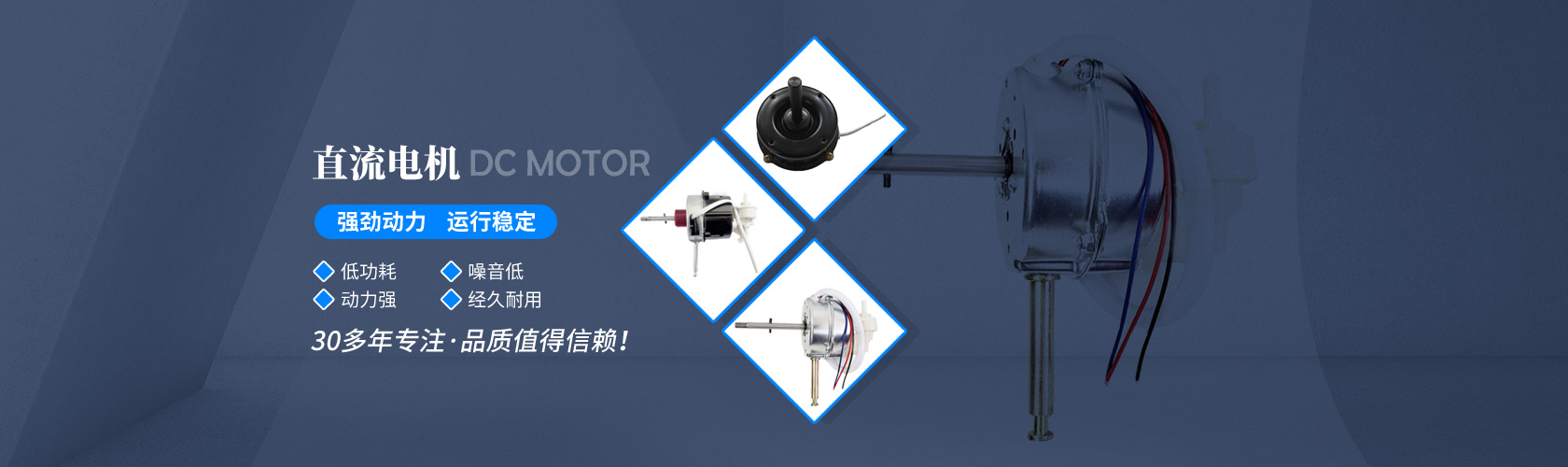

Tips for using DC deceleration motors

There are many aspects to the use of DC deceleration motors,including their application scope.They are most commonly used in the mechanical manufacturing industry.With the development of the stationery industry,the application scope of DC deceleration motors has entered a new level.Compared with ordinary DC motors,DC deceleration motors add a gearbox,which is a deceleration structure.This deceleration structure can adjust the speed to a more accurate range.So,what are the specific skills for using DC deceleration motors?

1.First,align the centerline of the management center of the DC reduction motor with the center,and then start it again,as this will increase the service cycle of the DC reduction motor.

2.Adjust the stability of the motor base and maintain the lubrication of the motor,so as not to cause significant vibration and noise.If there is significant noise and vibration,it should be due to damage to the transmission gear.Immediate maintenance and installation of safety devices are necessary.

3.Sharp objects should not be used to strike the output shaft of the motor,as it can easily cause damage to internal parts of the motor.

4.When using a DC reduction motor,try to avoid the working area of the motor as much as possible,unless it is for actual operation of air or oil drain plugs,and only approach the working area.Every application must carefully examine the condition of the motor,and it is prohibited to apply it when the motor parts are loose or lack lubricating grease.

The above are the usage tips for DC reduction motors.When applying the operation process,we should follow the specific steps and standards of the motor,and use methods to prevent the occurrence of some small problems,increase the service life of the machine equipment,and improve the working efficiency of the motor.